Aircraft cabin air quality monitoring refers to the continuous measurement and monitoring of the air quality inside an aircraft cabin. This includes monitoring the levels of various contaminants, such as particles, volatile organic compounds (VOCs), and gases such as carbon monoxide and ozone.

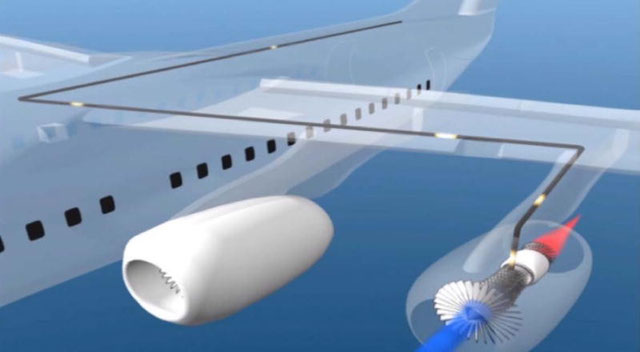

Aircraft cabin air is typically supplied through the engine bleed air system, which compresses and cools air from the engine and supplies it to the cabin. The quality of cabin air can be impacted by various factors, such as oil leaks, engine wear, and the presence of chemicals and pollutants in the environment.

Continuous monitoring of cabin air quality is important for ensuring passenger and crew safety, as well as maintaining the comfort and well-being of those on board. In-flight cabin air quality monitoring systems typically use sensors and control systems to provide real-time data on air quality, and can alert crew members to any deviations from acceptable limits.

By monitoring cabin air quality continuously, airlines can quickly identify and address any issues related to cabin air quality, such as leaks or contaminants, helping to ensure the safety and comfort of passengers and crew. Monitoring cabin air quality is a critical aspect of aircraft operation and maintenance.

Aircraft cabin air quality has generated considerable cabin crew and passengers’ concern and controversy in the past years, with oil contamination by bleed air being one of the subjects.

Outline of bleed air system on a jet aircraft. (courtesy of Capt. Tristan Loraine).

Well, no more guessing.

Real time continuous monitoring of aircraft cabin air for oil free compliance is now possible with the Oil Supervisor.

The system has additional options to also monitor dew point, CO, CO2, etc.